TAC Xenta 421A SCHNEIDER Input module

Brand:SCHNEIDER Model number:TAC Xenta 421A

Country of origin: France Product weight:0.55kg

HS code:853710119

Product Details:

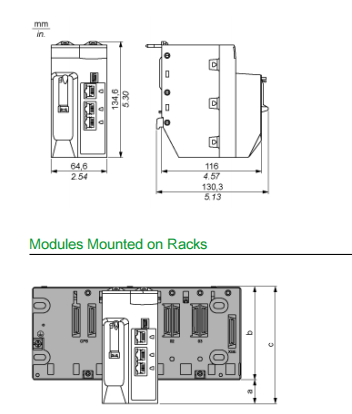

Product Dimensions:

The Schneider Electric TAC Xenta 421A is a compact, programmable controller designed for building automation and control systems, specifically within the TAC Vista system architecture (now part of the EcoStruxure Building Operation system). It functions as a LonWorks-based device used to manage and control Heating, Ventilation, and Air Conditioning (HVAC) applications.

Product Type: Programmable Controller, Room Controller

Series/Platform: TAC Xenta 400 Series

Communication Protocol: LonWorks (FTT-10A Free Topology Transceiver)

Processor: Neuron Chip

I/O Configuration: The 421A is a fixed I/O controller, often tailored for specific HVAC applications:

Universal Inputs: Typically 8 points (can be configured for voltage, resistance, or digital contact).

Digital Inputs: Often 2 points (for contacts, switches).

Analog Outputs: Typically 4 points (0-10 V DC).

Digital (Relay) Outputs: Typically 6 points (for controlling fans, compressors, or pumps).

Power Supply: $24 \text{ V AC/DC}$

Operating Temperature: Usually $0 \text{ to } 50^\circ\text{C}$ ($32 \text{ to } 122^\circ\text{F}$)

Programming: Programmed using the XBuilder software tool, which allows for function block programming and configuration.

Compatibility: Designed to integrate with the TAC Vista Building Management System (BMS) for centralized monitoring and control.

LonWorks Networking: Utilizes the robust, decentralized LonWorks protocol, which allows for reliable peer-to-peer communication and distribution of control tasks across the network.

Field Programmability: The controller is fully programmable using XBuilder, offering flexibility to adapt control strategies for diverse and complex HVAC applications, unlike fixed-function controllers.

Versatile I/O: The mix of universal inputs and various outputs (analog and digital) makes it suitable for controlling standard HVAC equipment like air handling units (AHUs), fan coil units (FCUs), or central plant components.

TAC Vista Integration: Seamlessly integrates with the TAC Vista BMS, providing operators with sophisticated graphics, alarms, trends, and scheduling capabilities through a centralized operator workstation.

Cost-Effective Control: Its compact size and integrated I/O points offer a cost-effective solution for providing sophisticated control logic at the equipment level.

Legacy Status: The TAC Xenta series is a legacy platform. Users should check the current product lifecycle status and consider migration paths to newer platforms like EcoStruxure Building Operation for new projects or system expansions.

Grounding and Shielding: Proper grounding and shielding of the LonWorks communication cable (LonTalk) are essential to prevent network interference and ensure reliable communication. Follow installation guidelines strictly.

Wiring Practices: Ensure all wiring adheres to local electrical codes and the manufacturer's recommendations. Use the appropriate wire gauge for power and I/O connections, and observe the maximum current ratings for the relay outputs.

Power Requirements: Confirm that the $24 \text{ V}$ power supply is stable and correctly sized to meet the controller's power consumption and the connected output loads.

Configuration Tools: Programming and configuration require specific software (XBuilder) and knowledge of LonWorks network management tools, making it distinct from standard PLC or BACnet controllers.

The TAC Xenta 421A is primarily used in commercial and institutional buildings to provide localized, intelligent control over mechanical equipment.

Air Handling Units (AHUs): Controlling the sequence of operation for AHU functions, including fan speed, damper positions, heating/cooling coil valves, and economizer control.

Central Plant Equipment: Managing the control loops for chillers, boilers, or cooling towers in smaller systems.

Variable Air Volume (VAV) Systems: Although the 421A is often an AHU controller, it may coordinate with VAV box controllers for zone-level demand control.

Energy Management: Implementing optimal start/stop, peak demand limiting, and other energy-saving strategies at the equipment level, reporting energy data back to the central TAC Vista BMS.

General Equipment Control: Controlling other building services that require a mix of inputs and outputs, such as lighting panels or specialized exhaust fans, integrated into the overall building control network.

We have the same series of models in stock. If you don't find the model you need, please contact us and we will provide you with an official quotation!

SCHNEIDER140CRA21220

SCHNEIDERBMXDAI1604

SCHNEIDER140XTS00200

SCHNEIDER140XBP01600

SCHNEIDERLMC058

SCHNEIDERTM2ALM3LT

SCHNEIDERHMIGXO3501

SCHNEIDERCAD326BD

SCHNEIDERNS250L (160 A)

SCHNEIDER750XBXH-24D

SCHNEIDERATV28HU18N4

SCHNEIDERXC1-ZA2

SCHNEIDERLC1-D09F7

SCHNEIDERLC1D18E7

SCHNEIDERLC1-D09E7

SCHNEIDERLC1-D12E7

SCHNEIDERLC1-D32E7

SCHNEIDERXTCE025C10TD

SCHNEIDERXS530BSDBL2

SCHNEIDERXS8C4A4PCG13

SCHNEIDERLCID65F7

SCHNEIDERTSXP571634M

SCHNEIDERXSAV11373

SCHNEIDERATV610U55N4

SCHNEIDERBMXDDO1602

SCHNEIDERBMXDDO3202K

Colour:new Warranty: 12 months

Lead Time:3-day working day Price: Please contact us

Shipping Port: Xiamen, China Payment:T/T

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online servi

Our service:

Fast delivery, and can be used with your express account.

Competitive Price

Free Shipping

One-year warranty