VRDM368/50LNBOB SCHNEIDER Input module

Brand:SCHNEIDER Model number:VRDM368/50LNBOB

Country of origin: France Product weight:0.55kg

HS code:853710119

Product Details:

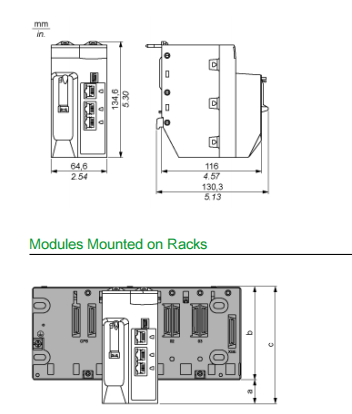

Product Dimensions:

The VRDM368/50LNBOB is a specific model of stepper motor manufactured by Schneider Electric, often falling under their motion control or Lexium product line. This motor is designed for precise positioning and speed control in demanding automation applications.

Product Type: Two-phase Stepper Motor

Series: VRDM3

Motor Size (Flange/Frame Size): This model typically corresponds to a NEMA 34 frame size (often $85 \text{ mm}$ square).

Holding Torque: The "50" in the part number often relates to the holding torque specification, which for this size and series is substantial, usually ranging from $5.0 \text{ Nm}$ to $7.0 \text{ Nm}$ (Newton-meters), depending on the exact winding.

Step Angle: Standard step angle is typically $1.8$ degrees (200 steps per revolution).

Number of Leads: Usually 4 leads (Bipolar winding) for connection to a stepper drive.

Shaft Type: Often features a single-ended output shaft.

Electrical Characteristics: Specific current and voltage ratings depend on the winding (e.g., $4.2 \text{ A}$ phase current), but the motor is optimized for high torque at lower speeds.

Protection: Generally rated for IP40 protection, meaning it should be mounted within a protective enclosure.

Feedback: The "NBOB" typically indicates No Brake and No Encoder (or other feedback device) on the motor shaft.

High Holding Torque: Stepper motors inherently provide high torque at zero speed (holding torque), making the VRDM368/50LNBOB excellent for applications requiring the load to be securely held in a stationary position without continuous power or complex feedback.

Excellent Positional Accuracy: Due to the discrete step nature of its movement, it offers highly accurate and repeatable positioning, particularly when used with microstepping drives.

Reliability and Longevity: Stepper motors are brushless, resulting in a low maintenance requirement and long operational life, making them cost-effective over time.

Open-Loop Control: Steppers can typically be run in an open-loop system, simplifying the control architecture by eliminating the need for an encoder, which reduces system cost and complexity (consistent with the "NBOB" designation).

Resonance and Vibration: Stepper motors can experience resonance at certain speeds, which may lead to vibration, noise, and loss of steps. Use a quality microstepping drive and damping techniques to mitigate this.

Overheating: Running the motor at its maximum rated current or at continuous high speeds without proper heat sinking or cooling may cause overheating, potentially leading to torque loss or premature winding failure.

Torque Drop-off: Unlike servo motors, a stepper motor's torque decreases significantly as the speed increases. Ensure the application's required speed is within the motor's effective torque-speed curve.

Step Loss: In high-speed or high-load conditions, a stepper motor can lose steps (miss an commanded step) without the control system knowing it in an open-loop system. If position confirmation is critical, consider adding an external encoder or switching to a closed-loop stepper or servo system.

The VRDM368/50LNBOB stepper motor is ideal for various industrial automation and motion control tasks requiring precise, discrete movements and strong holding capability.

Indexing and Positioning Tables: Used for accurately moving parts or tools to specific locations in assembly machines or quality control systems.

Labeling and Packaging Machines: Driving conveyors, film feeders, and cutting mechanisms where the movement must be synchronized with production cycles.

CNC Equipment (Low-End): Utilized for the linear axes (X, Y, Z) in smaller or less-demanding CNC routers, engravers, or 3D printers.

Fluid Dispensing and Dosing: Controlling the precise amount of liquid or material dispensed by turning a lead screw or metering pump.

Scanning and Optics: Moving mirrors, lenses, or sensors in precision optical or medical devices.

We have the same series of models in stock. If you don't find the model you need, please contact us and we will provide you with an official quotation!

SCHNEIDER140CRA21220

SCHNEIDERBMXDAI1604

SCHNEIDER140XTS00200

SCHNEIDER140XBP01600

SCHNEIDERLMC058

SCHNEIDERTM2ALM3LT

SCHNEIDERHMIGXO3501

SCHNEIDERCAD326BD

SCHNEIDERNS250L (160 A)

SCHNEIDER750XBXH-24D

SCHNEIDERATV28HU18N4

SCHNEIDERXC1-ZA2

SCHNEIDERLC1-D09F7

SCHNEIDERLC1D18E7

SCHNEIDERLC1-D09E7

SCHNEIDERLC1-D12E7

SCHNEIDERLC1-D32E7

SCHNEIDERXTCE025C10TD

SCHNEIDERXS530BSDBL2

SCHNEIDERXS8C4A4PCG13

SCHNEIDERLCID65F7

SCHNEIDERTSXP571634M

SCHNEIDERXSAV11373

SCHNEIDERATV610U55N4

SCHNEIDERBMXDDO1602

SCHNEIDERBMXDDO3202K

Colour:new Warranty: 12 months

Lead Time:3-day working day Price: Please contact us

Shipping Port: Xiamen, China Payment:T/T

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online servi

Our service:

Fast delivery, and can be used with your express account.

Competitive Price

Free Shipping

One-year warranty