TAC Xenta 422 SCHNEIDER Input module

Brand:SCHNEIDER Model number:TAC Xenta 422

Country of origin: France Product weight:0.55kg

HS code:853710119

Product Details:

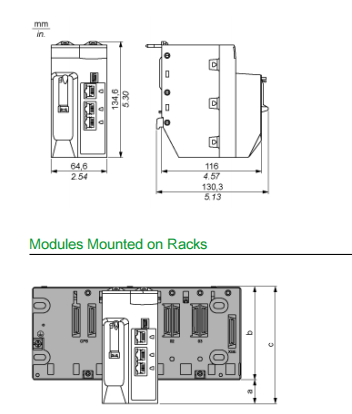

Product Dimensions:

The Schneider Electric TAC Xenta 422 is a LonWorks-based controller specifically designed for use in Building Management Systems (BMS). It is a highly flexible and powerful universal input/output (I/O) controller within the legacy TAC Vista or modern EcoStruxure Building Operation platforms, typically used for regulating HVAC, lighting, and other building services.

Product Type: LonWorks Universal Input/Output Controller

Communication Protocol: LonTalk protocol, FTT-10A Free Topology twisted pair wiring

Inputs: Features 12 universal inputs. These inputs can be individually configured for a variety of sensor types:

Analog Input (AI): Resistance-based sensors (e.g., NTC 10k $\Omega$ thermistors), voltage ($0-10 \text{ VDC}$), or current ($0-20 \text{ mA}$) (requires external resistor).

Digital Input (DI): Potential-free contacts for status monitoring.

Outputs: Equipped with 8 digital outputs (DO) and 4 analog outputs (AO).

Digital Outputs: Used for on/off control of equipment like fans, pumps, or lights, typically driving relays or contactors. They are designed as $24 \text{ VAC/VDC}$ triacs.

Analog Outputs: Provide modulating control signals, typically $0-10 \text{ VDC}$, for devices such as VAV box actuators, dampers, or valves.

Power Supply: $24 \text{ VAC}$ (typically $50/60 \text{ Hz}$)

Processor: Neuron 3150 Chip (specific to LonWorks devices)

Configuration and Programming: Configurable using the TAC Menta graphical programming tool and commissioned using standard LonWorks tools.

Mounting: DIN rail mountable for easy installation in control cabinets.

High Flexibility: The 12 universal inputs provide exceptional flexibility, allowing the controller to interface with almost any common building sensor (temperature, humidity, pressure, flow) without needing specialized modules.

Integrated LonWorks Communication: The native LonWorks FTT-10A connectivity allows the controller to be easily integrated into a distributed control network, enabling peer-to-peer communication and simplified network architecture.

Modular and Scalable I/O: The fixed combination of 12 inputs, 8 digital outputs, and 4 analog outputs provides a well-balanced mix for controlling medium to large-sized zones or central plant equipment.

Graphical Programming: Utilizing the Menta tool, control engineers can implement complex control sequences using intuitive function blocks, reducing programming time and simplifying troubleshooting.

Reliability: Built for continuous operation in HVAC environments, providing stable and dependable control over critical building systems.

Legacy Status: The TAC Xenta line is considered a legacy product within Schneider Electric's offering. While supported, new installations are often directed towards the EcoStruxure Building Operation platform using IP-based controllers (e.g., SmartX IP Controllers).

Power Requirements: Ensure the controller is supplied with a stable $24 \text{ VAC}$ power source within the specified tolerance. Incorrect voltage can damage the unit.

Wiring Standards: All wiring, especially for the digital outputs (triacs), must comply with local electrical codes and the manufacturer's maximum current ratings to prevent overheating or fire hazards.

Commissioning Tools: Proper configuration and commissioning require specialized LonWorks network management tools and the TAC Menta programming software.

Grounding and Shielding: For stable communication, particularly with analog signals, proper grounding and shielding of sensor and communication cables is essential to minimize electrical interference (noise).

The TAC Xenta 422 is typically used as a primary controller for managing mid-sized to large zones and equipment in commercial buildings.

Air Handling Units (AHUs): Used to control supply fans, return fans, pre-heat coils, cooling coils, dampers, and alarms, utilizing its extensive I/O count for complex sequences.

Boiler and Chiller Plant Control: Implementing control loops for temperature, pressure, and staging of central plant equipment.

Pumps and Distribution Systems: Managing variable speed drives (VSDs), pump staging, and valve positioning in hot water and chilled water distribution loops.

Large Zone Control: Serving as the main controller for floors or large open office areas, managing multiple Variable Air Volume (VAV) boxes or fan coil units (FCUs) via peer-to-peer LonWorks communication.

We have the same series of models in stock. If you don't find the model you need, please contact us and we will provide you with an official quotation!

SCHNEIDER140CRA21220

SCHNEIDERBMXDAI1604

SCHNEIDER140XTS00200

SCHNEIDER140XBP01600

SCHNEIDERLMC058

SCHNEIDERTM2ALM3LT

SCHNEIDERHMIGXO3501

SCHNEIDERCAD326BD

SCHNEIDERNS250L (160 A)

SCHNEIDER750XBXH-24D

SCHNEIDERATV28HU18N4

SCHNEIDERXC1-ZA2

SCHNEIDERLC1-D09F7

SCHNEIDERLC1D18E7

SCHNEIDERLC1-D09E7

SCHNEIDERLC1-D12E7

SCHNEIDERLC1-D32E7

SCHNEIDERXTCE025C10TD

SCHNEIDERXS530BSDBL2

SCHNEIDERXS8C4A4PCG13

SCHNEIDERLCID65F7

SCHNEIDERTSXP571634M

SCHNEIDERXSAV11373

SCHNEIDERATV610U55N4

SCHNEIDERBMXDDO1602

SCHNEIDERBMXDDO3202K

Colour:new Warranty: 12 months

Lead Time:3-day working day Price: Please contact us

Shipping Port: Xiamen, China Payment:T/T

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online servi

Our service:

Fast delivery, and can be used with your express account.

Competitive Price

Free Shipping

One-year warranty