IR425-D4-2 Bently Nevada Processor module

Brand:BENTLY NEVADA Model number:IR425-D4-2

Country of origin: U.S. Product weight:0.55kg

HS code:8517623990

Product Details:

Product Dimensions:

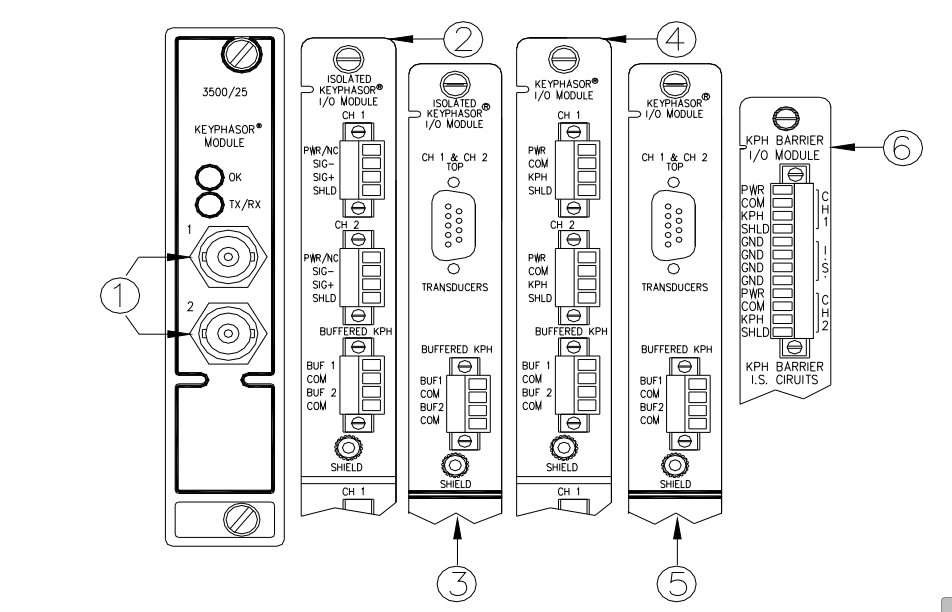

A Bently Nevada Processor Module, such as the Protection Processing Module (PPM) in the Orbit 60 series or various Monitor Modules within the 3500 series, serves as the analytical heart of a machinery monitoring system. It receives raw signals from a wide array of transducers (e.g., proximity probes, accelerometers, velocity sensors, temperature sensors), performs sophisticated signal conditioning and processing, and then generates precise measurements and statuses. These measurements are used for machinery protection (tripping or alarming when conditions exceed safe limits) and condition monitoring (providing data for diagnostic analysis).

Functionality: These modules extract vital machinery measurements (e.g., vibration amplitude, phase, thrust position, speed, temperature, pressure). They apply advanced signal processing techniques like filtering (bandpass, lowpass, highpass), integration, and differentiation. Based on configured setpoints, they determine alarm conditions (Alert, Danger) and can initiate machine trips through associated relay modules to prevent catastrophic failure. They also publish processed data for further analysis by condition monitoring software.

Types: Bently Nevada offers different processor modules tailored to specific measurement types and system architectures. Examples include:

Protection Processing Module (PPM) (e.g., Orbit 60 Series): Acts as the computational engine for the entire system, handling multiple sensor types and performing alarm determinations.

Monitor Modules (e.g., 3500 Series): Specialized modules for specific measurements like radial vibration, thrust position, speed, temperature, or dynamic pressure. Each monitor module typically handles a set number of channels for a particular measurement type.

Key Features:

High-Speed Data Acquisition: Capable of acquiring dynamic data at high sample rates.

Advanced Signal Processing: Built-in algorithms for filtering, integration, 1X/2X/nX amplitude and phase tracking, SMAX, and more.

Configurable Alarming: Multiple alarm setpoints (Alert, Danger) with adjustable time delays.

Protection States: Ability to define different protection states with unique alarm setpoints, controlled by discrete inputs or measurement ranges.

Robust Design: Engineered for harsh industrial environments, including extreme temperatures and vibrations.

Cyber Secure: Newer generations, like the Orbit 60, are designed with intrinsic cybersecurity features.

Modular Architecture: Plugs into a system chassis (rack) with other modules (e.g., power supplies, interface modules, I/O modules).

Specific parameters vary by module type and series (e.g., 3500 series vs. Orbit 60 series):

Input Channel Types: Radial Vibration, Axial (Thrust) Position, Eccentricity, Acceleration, Velocity, Speed (Keyphasor), Temperature (RTD/TC), Dynamic Pressure, Piston Rod Drop/Position.

Number of Channels: Typically 2 to 4 channels per monitor module, with the PPM handling a larger aggregate number of sensors.

Measurement Accuracy: Typically within ±0.33% of full-scale for dynamic measurements.

Frequency Range: Varies by sensor and measurement type, from very low frequencies (e.g., 0.0626 Hz for vibration) up to 40,000 Hz or 120,000 rpm for speed.

Alarm Setpoints: Up to four setpoint levels per measurement, with adjustable alarm time delays (e.g., 100 ms to 60 sec for vibration/position).

Power Consumption: Varies by module, typically in the range of a few watts (e.g., 12.7W max for Orbit 60 PPM).

Operating Temperature: Standard industrial range, typically -30°C to +65°C (-22°F to +150°F).

Hazardous Area Certifications: Available with certifications like CSA/NRTL/C (Class I, Div. 2), ATEX, IECEx for use in explosive environments.

Rack Slot Requirement: Each processor module typically occupies one slot in the system chassis.

Enhanced Machinery Protection: Provides continuous, high-fidelity monitoring and rapid alarming/tripping to prevent catastrophic failures and extend machine life.

Reduced Downtime: Early detection of developing faults allows for proactive maintenance, significantly reducing unplanned outages.

Optimized Performance: Enables precise monitoring of machine health, allowing operators to optimize machine performance and efficiency.

Data-Driven Decisions: Generates rich data for advanced diagnostics, empowering maintenance personnel to make informed decisions.

Scalability and Flexibility: Modular design allows systems to be tailored to specific machine trains and expanded as monitoring needs evolve.

Compliance and Reliability: Designed to meet stringent industry standards (e.g., API 670, SIL certification for some systems) for critical machinery protection.

Integrated Diagnostics: Seamless integration with Bently Nevada's condition monitoring software for comprehensive data analysis and visualization.

System Integration: These modules are part of a larger Bently Nevada monitoring system (e.g., 3500 Series, Orbit 60 Series) and require a compatible chassis, power supplies, and communication modules.

Transducer Compatibility: Ensure the processor module is compatible with the specific type and model of transducers being used.

Configuration Complexity: Proper configuration of alarm setpoints, filtering, and measurement parameters is crucial for accurate protection and monitoring. This typically requires specialized software and expertise.

Environmental Control: While rugged, maintaining the operating environment within specified temperature and humidity ranges is vital for long-term reliability.

Calibration and Maintenance: Regular calibration of transducers and system checks are necessary to maintain accuracy.

Cybersecurity: For network-connected systems, adhere to cybersecurity best practices, especially for newer, intrinsically cyber-secure systems.

Obsolescence Management: For older 3500 series modules, consider long-term support, spare parts availability, and potential upgrade paths.

Bently Nevada Processor Modules are indispensable in industries with critical rotating and reciprocating machinery:

Oil and Gas:

Turbines (gas, steam, hydro) and compressors in refineries, pipelines, and offshore platforms.

Pumps, motors, and generators in oil & gas facilities.

Power Generation:

Steam turbines, gas turbines, and generators in thermal, nuclear, and renewable power plants.

Boiler feed pumps and auxiliary machinery.

Chemical and Petrochemical:

Reactor compressors, pumps, and mixers where process continuity and safety are paramount.

Pulp and Paper:

Monitoring large paper machines, refiners, and dryers.

Mining and Metals:

Monitoring large crushers, mills, and heavy machinery.

Manufacturing:

Protecting critical motors, fans, and specialized machinery in high-volume production lines.

We have the same series of models in stock. If you don't find the model you need, please contact us and we will provide you with an official quotation!

BENTLY NEVADA 330100-50-01

BENTLY NEVADA 3500/15-04-00

BENTLY NEVADA 128710-01

BENTLY NEVADA 129525-0050-02

BENTLY NEVADA 18639-01

BENTLY NEVADA IR425-D4-2

BENTLY NEVADA 330425 -01-05

BENTLY NEVADA 138493-01

BENTLY NEVADA 89477-30

BENTLY NEVADA P1407030-02006

Colour:new Warranty: 12 months

Lead Time:3-day working day Price: Please contact us

Shipping Port: Xiamen, China Payment:T/T

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online servic

Our service:

Fast delivery, and can be used with your express account.

Competitive Price

Free Shipping

One-year warranty