184573-99 Bently Nevada Servo Controller

Brand:BENTLY NEVADA Model number:184573-99

Country of origin: U.S. Product weight:0.55kg

HS code:8517623990

Product Details:

Product Dimensions:

A Bently Nevada-relevant "Servo Controller" would likely be a specialized module or system designed for precise, closed-loop control of a servo-actuated mechanism, often in conjunction with their renowned proximity and vibration sensors. This controller would interpret machine condition data (e.g., shaft position, valve lift) and issue commands to a servo motor or actuator to maintain optimal operating parameters or respond to protection logic.

Functionality: This type of controller would take feedback from high-precision Bently Nevada sensors (like LVDT-based valve position sensors or proximity probes) and use this information in a control loop to drive a servo motor or electro-hydraulic servo valve. Its primary purpose would be to precisely position a component (e.g., a turbine control valve, a rotor balancing mechanism, or a dampener) based on control signals and real-time machine feedback. It would often integrate with a larger protection system to ensure safe operation.

Key Features:

High Precision Feedback Integration: Directly interfaces with Bently Nevada's high-resolution sensors for accurate position or displacement feedback.

Closed-Loop Control: Implements PID (Proportional-Integral-Derivative) or advanced control algorithms for stable and accurate positioning.

Fast Response Time: Critical for quick adjustments in dynamic machinery applications.

Robust Industrial Design: Built to withstand the harsh environments typical of power generation, oil & gas, and process industries.

Communication Interfaces: Connectivity to distributed control systems (DCS), PLCs, or Bently Nevada's own monitoring systems for supervisory control and data exchange.

Safety Interlocks: Designed with features to integrate into existing safety systems, potentially including fail-safe mechanisms for valve closure or emergency shutdown.

Input Feedback: Compatible with LVDT sensors (e.g., for valve position), proximity probes (for shaft position), or other precise position transducers.

Output Type: Analog voltage or current output to drive a servo valve driver or a pulse/direction interface for a servo motor amplifier.

Control Loop Update Rate: High frequency (e.g., kHz range) for rapid and precise control.

Accuracy/Resolution: Dependent on the application, but typically high resolution for fine control of position.

Power Supply: Industrial standard voltages (e.g., 24 VDC, 120 VAC).

Operating Temperature: Wide industrial temperature range (e.g., -20°C to +65°C).

Communication Protocols: Often support industrial protocols like Modbus TCP/RTU, Ethernet/IP, or proprietary protocols for integration into plant control systems.

Optimized Machine Performance: Enables precise control of critical components (like control valves), leading to improved efficiency and performance of turbomachinery.

Enhanced Protection: By integrating with Bently Nevada's protection systems, it contributes to machinery safety by ensuring components are in their correct positions during normal operation and fault conditions.

Reduced Wear and Tear: Precise control minimizes overshoot and oscillations, reducing mechanical stress on actuators and associated machinery.

High Reliability: Leveraging Bently Nevada's expertise in robust industrial solutions, such a controller would offer high reliability for critical applications.

Integration with Monitoring: Seamless data sharing and control interaction with Bently Nevada's condition monitoring and protection systems provide a holistic view of machine health and control.

Specific Application Needs: The exact type and specifications of a "servo controller" would be highly dependent on the precise application, whether it's for fuel valve control, rotor positioning, or another specialized function within turbomachinery.

Integration Complexity: Interfacing a specialized controller with existing plant DCS, PLCs, and Bently Nevada monitoring systems requires careful planning and expertise in communication protocols and control logic.

Sensor Compatibility: Ensure full compatibility with the specific Bently Nevada sensors (e.g., LVDTs, Proximity Probes) used for feedback.

Safety System Design: Critical control applications require rigorous safety integrity level (SIL) assessments and proper integration with emergency shutdown (ESD) systems.

Calibration and Tuning: Servo controllers require precise calibration and tuning for optimal performance, often involving specialized software and experienced technicians.

Maintenance and Support: Given the specialized nature, consider the availability of expert support and spare parts for long-term maintenance.

If Bently Nevada offered a "Servo Controller" product, it would likely be found in highly specialized applications within their core industries:

Turbomachinery Control:

Fuel Valve Control: Precisely positioning gas or steam turbine fuel valves to control speed and power output, often in conjunction with overspeed protection.

Compressor Anti-Surge Control: Actuating anti-surge valves with high precision to protect compressors from unstable operation.

Steam Turbine Governor Control: Interfacing with turbine governors for precise speed and load control.

Hydroelectric Power Generation:

Wicket Gate Control: Precisely positioning wicket gates in hydro turbines for efficient water flow and power generation.

Critical Valve Actuation:

Any application requiring highly accurate and repeatable positioning of critical valves in oil & gas, refining, or chemical processing.

Rotor Positioning/Lift Systems:

Controlling hydraulic systems for precise rotor lift or axial positioning during startup/shutdown or maintenance, integrating feedback from proximity probes.

We have the same series of models in stock. If you don't find the model you need, please contact us and we will provide you with an official quotation!

BENTLY NEVADA 330180-X0-00

BENTLY NEVADA 330780-X0-00

BENTLY NEVADA 330850-X0-00

BENTLY NEVADA 3500/42-01/00

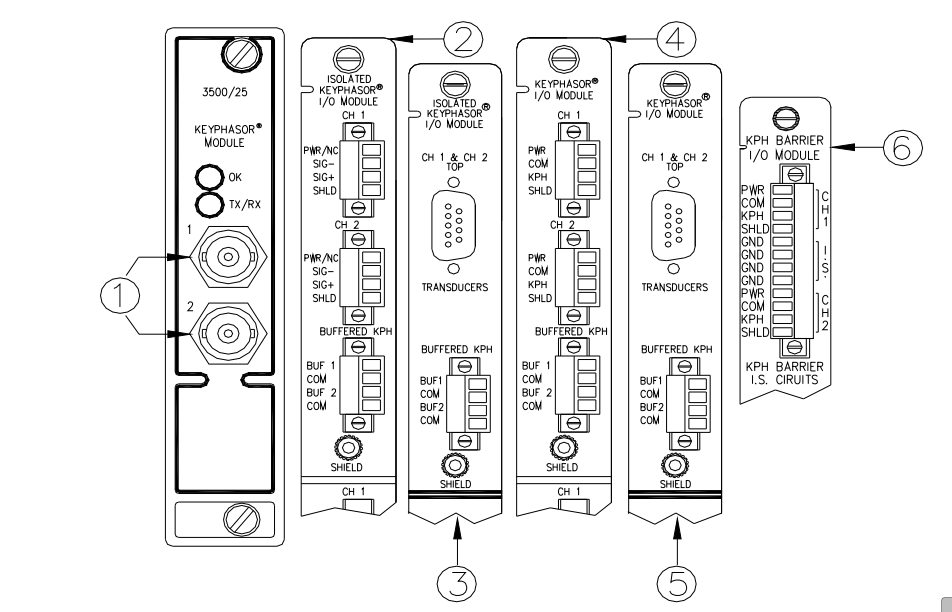

BENTLY NEVADA 3500/25-01-03-02 149369-01

BENTLY NEVADA 3500/25-01-03-02 135473-01

BENTLY NEVADA 176449-08

BENTLY NEVADA 106M2686-00

BENTLY NEVADA 184573-98

BENTLY NEVADA 184684-01

Colour:new Warranty: 12 months

Lead Time:3-day working day Price: Please contact us

Shipping Port: Xiamen, China Payment:T/T

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online servic

Our service:

Fast delivery, and can be used with your express account.

Competitive Price

Free Shipping

One-year warranty