2300/20-RU Bently Nevada Communication Interface

Brand:BENTLY NEVADA Model number:2300/20-RU

Country of origin: U.S. Product weight:0.55kg

HS code:8517623990

Product Details:

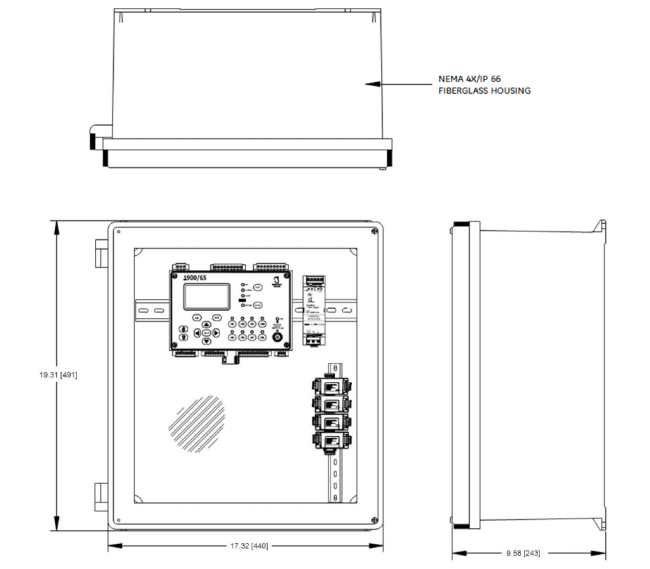

Product Dimensions:

Bently Nevada Communication Interface modules are designed to provide extensive communication capabilities for all monitored values and statuses within a Bently Nevada monitoring rack. They bridge the gap between the specialized machinery protection data and the broader plant control and IT infrastructure.

Functionality: These modules gather critical machinery data (like vibration, temperature, displacement, and speed readings, along with alarm statuses) from the monitoring modules within the 3500 rack. They then translate this proprietary data into standard industrial communication protocols, allowing other systems (DCS, PLC, SCADA, CMMS, or Bently Nevada's System 1 software) to access, display, and archive this information. They also facilitate remote configuration and data acquisition from the monitoring rack.

Key Types/Examples:

3500/92 Communication Gateway Module: This is a prominent example, providing both Ethernet TCP/IP and serial (RS232/RS422/RS485) communication capabilities. It supports protocols like Modbus/TCP, serial Modbus, and proprietary Bently Nevada protocols.

3500/22M Transient Data Interface (TDI): This module serves as the primary interface between the 3500 monitoring system and Bently Nevada's System 1 machinery management software. It combines the functionality of a Rack Interface Module (RIM) with data collection capabilities, continuously gathering steady-state and transient dynamic (waveform) data for analysis.

3500/91 EGD (Ethernet Global Data) Communication Gateway: Specifically designed for integration with controllers using the Ethernet Global Data (EGD) protocol, providing fast response times suitable for control applications.

Key Features:

Protocol Conversion: Translates internal Bently Nevada data into industry-standard protocols.

Data Aggregation: Collects and consolidates data from multiple monitoring modules within the rack.

Configuration Access: Allows remote access for configuring the 3500 rack and its modules.

Diagnostic Information: Provides status and diagnostic data about the communication link and the module itself.

Robust Design: Built to meet the stringent requirements of industrial environments.

Parameters vary depending on the specific communication interface module, but common aspects include:

Supported Protocols: Modbus/TCP, Modbus (serial), Ethernet Global Data (EGD), OPC UA (on newer systems), proprietary Bently Nevada protocols.

Communication Interfaces: Ethernet (RJ-45, 10/100 Mbps), Serial (RS-232, RS-422, RS-485).

Power Consumption: Typically low, e.g., 5.0 to 5.6 watts for the 3500/92.

Data Types: Collects current proportional values with timestamps, module statuses, alarm statuses, and potentially dynamic waveform data.

Data Update Rate: Data collection rates depend on rack configuration but are generally fast enough for online monitoring, often within 1 second for all modules in a rack.

Operating Temperature: Wide industrial range, typically -30°C to +65°C (-22°F to +150°F).

Storage Temperature: -40°C to +85°C (-40°F to +185°F).

Humidity: 95% non-condensing.

Physical Dimensions: Designed to fit into standard 3500 Series monitoring racks (e.g., 241 mm H x 24.4 mm W x 242 mm D for the 3500/92).

Rack Slot Requirement: Typically occupies one slot in the 3500 rack, usually Slot 1 (Rack Interface Module slot).

Certifications: Often compliant with API 670, CE, CSA, UL, ATEX, etc.

Seamless Integration: Enables easy integration of machinery health data with plant-wide control systems and enterprise software, providing a unified view of operations.

Enhanced Diagnostics: Facilitates the transfer of rich diagnostic data, including waveforms, to advanced analysis software like System 1, allowing for in-depth root cause analysis and proactive maintenance.

Improved Decision Making: Provides real-time and historical machinery information, empowering operators and maintenance personnel to make informed decisions to prevent failures and optimize asset performance.

Increased Reliability: By connecting protection systems to condition monitoring platforms, it enhances the overall reliability strategy by combining protection (tripping) with predictive maintenance.

Flexibility: Supports multiple communication protocols, offering compatibility with a wide range of industrial control systems and IT infrastructure.

Robustness: Engineered for continuous operation in harsh industrial environments, ensuring consistent data availability.

Cybersecurity Features: Newer generations incorporate features to ensure secure data transmission.

System Compatibility: Ensure the specific communication interface module is compatible with the version of the 3500 monitoring system firmware and the target host software (e.g., System 1, DCS).

Network Configuration: Proper network setup (IP addressing, subnet masks, gateway configuration) is crucial for reliable Ethernet communication.

Protocol Understanding: Familiarity with the chosen communication protocol (Modbus, EGD, etc.) is necessary for proper configuration and data mapping in the receiving system.

Data Latency: Understand the expected data update rates and potential latency, especially for critical real-time control applications, although Bently Nevada modules are generally designed for low latency.

Cybersecurity: Implement strong cybersecurity practices for network connections to protect sensitive machinery data.

Rack Slot Location: These modules often have specific slot requirements within the 3500 rack (e.g., Slot 1 for RIMs and TDIs).

Firmware Updates: Regularly check for and apply firmware updates to ensure optimal performance, security, and compatibility.

Documentation: Always refer to the specific module's operation and maintenance manual for detailed installation, configuration, and troubleshooting information.

Bently Nevada Communication Interface modules are indispensable in industries relying on critical rotating machinery:

Oil and Gas:

Connecting vibration monitoring systems on turbines, compressors, and pumps to plant DCS for integrated control and alarming.

Transmitting machinery health data from offshore platforms to onshore diagnostic centers.

Power Generation:

Interfacing turbine and generator protection systems with SCADA and plant historians for performance monitoring and outage planning.

Enabling remote diagnostics of critical rotating assets in power plants.

Petrochemical and Chemical Processing:

Providing machinery vibration and performance data to process control systems for operational adjustments and safety interlocks.

Pulp and Paper:

Monitoring and communicating the health of large motors, fans, and rolls to optimize production and prevent unplanned shutdowns.

Mining:

Integrating condition monitoring data from crushers, conveyors, and mill drives into mine control systems.

Other Heavy Industries:

Found in any facility with critical rotating machinery where continuous monitoring and integration with plant-wide systems are essential for safety, efficiency, and reliability.

We have the same series of models in stock. If you don't find the model you need, please contact us and we will provide you with an official quotation!

BENTLY NEVADA 3500/15-01-02-01

BENTLY NEVADA 2300/20

BENTLY NEVADA 24765-02-01

BENTLY NEVADA 330709-000-050-10-02-05

BENTLY NEVADA 3500/72-01-00

BENTLY NEVADA 2300/20-RU

BENTLY NEVADA 1900/65A-01-01-03-00-00

BENTLY NEVADA 3500/15 127610-01

BENTLY NEVADA 3500/22 138607-01

BENTLY NEVADA 3500/40 125680-01

Colour:new Warranty: 12 months

Lead Time:3-day working day Price: Please contact us

Shipping Port: Xiamen, China Payment:T/T

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online servic

Our service:

Fast delivery, and can be used with your express account.

Competitive Price

Free Shipping

One-year warranty