125808-06 Bently Nevada Output Module

Brand:BENTLY NEVADA Model number:125808-06

Country of origin: U.S. Product weight:0.55kg

HS code:8517623990

Product Details:

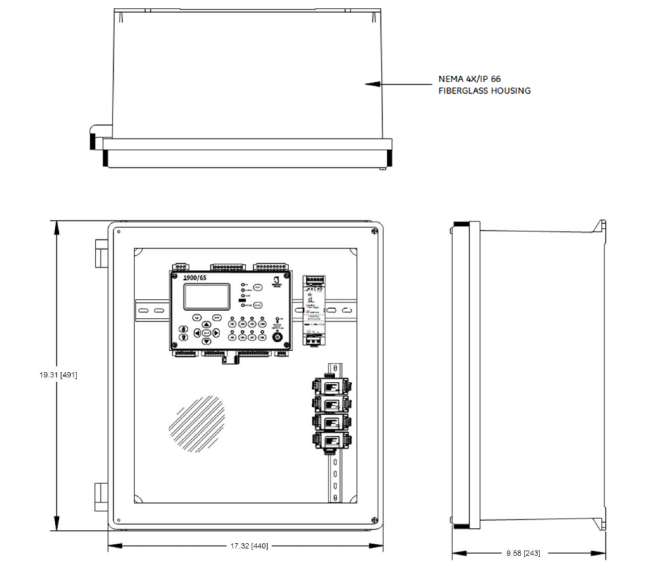

Product Dimensions:

A Bently Nevada Output Module typically refers to a module within a larger machinery protection system, such as the widely used 3500 Series Monitoring System. These modules receive processed data (e.g., vibration levels, thrust position, temperature) from monitor modules and generate outputs to trigger alarms, initiate machinery shutdowns, or transmit data to other control systems. They are critical for automating protective actions and integrating machinery health information into plant-wide control strategies.

Functionality: Bently Nevada Output Modules translate machinery condition data into actionable outputs. For example, if a vibration level exceeds a preset alarm threshold, the output module can activate an alarm light, sound a horn, or send a signal to a Distributed Control System (DCS) or PLC. Crucially, if a more severe trip threshold is exceeded, the module can initiate a machinery shutdown to prevent damage. They can also provide buffered outputs of raw transducer signals for further analysis.

Types:

Relay Modules (e.g., 3500/32, 3500/33): These modules provide discrete relay contacts that can be wired to activate external alarms, initiate machinery trips, or control auxiliary equipment. They are configurable for various alarm and trip logic (e.g., Normally Open/Normally Closed, energize to alarm/trip).

Communication Gateway/Interface Modules (e.g., 3500/92 Communication Gateway, 3500/93 SystemNET Gateway): While primarily for communication, these modules often include output functionalities by transmitting machinery data and alarm/status information to plant control systems (DCS, SCADA, PLCs) via industrial protocols like Modbus TCP/IP, OPC, or proprietary networks.

Buffered Output Modules: Some systems or specific monitor modules (e.g., Proximitor® monitors) may offer buffered outputs of the raw transducer signal. This allows external data acquisition systems or portable vibration analyzers to access the same high-fidelity data used by the protection system, without interfering with the primary monitoring path.

Key Features:

Programmable Setpoints: Alarm and trip setpoints are highly configurable to match specific machinery protection requirements.

Bypassing and Inhibit Functions: Features to temporarily bypass or inhibit trip logic during startup or maintenance, with appropriate safety interlocks.

First-Out Indication: For relay modules, the ability to indicate which alarm or trip occurred first in a sequence of events.

Voting Logic: In critical applications, multiple output modules can be configured with voting logic (e.g., 2-out-of-3) to prevent spurious trips.

System Integration: Designed for seamless integration with other Bently Nevada 3500 Series modules (monitors, power supplies, rack interface modules) and external control systems.

Safety Certifications: Often carry certifications for safety integrity levels (SIL) required for critical machinery protection applications.

Parameters depend on the specific output module:

Number of Channels/Relays: Typically 4, 6, 8, or more relays per module.

Relay Contact Ratings: Maximum voltage (e.g., 24VDC, 120VAC, 240VAC) and current (e.g., 5A) that the relay contacts can switch.

Relay Type: Form C (SPDT), Form A (SPST-NO), or Form B (SPST-NC).

Communication Protocols (for Gateway Modules): Ethernet TCP/IP (Modbus/TCP), Serial (Modbus RTU), OPC.

Power Consumption: Typically low power consumption, supplied by the system rack's power supply.

Operating Temperature: Standard industrial ranges, typically -30°C to +65°C (-22°F to +149°F).

Rack Space Requirement: How many slots the module occupies in the 3500 rack (e.g., 1 full-height rear slot).

Compliance and Certifications: Adherence to API 670 (American Petroleum Institute standard for machinery protection systems), CE, UL, CSA, ATEX for hazardous areas, and SIL ratings.

Enhanced Machinery Protection: Provides robust and reliable automatic protection against machinery failures, preventing costly damage and prolonged downtime.

Improved Safety: By initiating trips or alarms, these modules help safeguard personnel from potential hazards associated with machinery malfunctions.

Customizable Logic: Highly configurable alarm and trip logic allows tailoring to specific machine criticality and operational philosophies.

Seamless Integration: Designed to integrate flawlessly within the Bently Nevada monitoring ecosystem and with plant-wide control systems.

Data Availability: Communication gateway modules enable crucial machinery health data to be shared with control systems for enhanced operational awareness and predictive maintenance.

Reliability: Bently Nevada products are known for their exceptional reliability and long-term performance in demanding industrial environments.

System Compatibility: Ensure the specific output module is compatible with the Bently Nevada monitoring system (e.g., 3500 Series rack, monitor modules) and firmware versions.

Wiring and Installation: Proper wiring, grounding, and physical installation are crucial for reliable operation and adherence to safety standards. Refer to detailed product manuals.

Configuration Complexity: Configuration of alarm setpoints, voting logic, and communication parameters requires specialized knowledge and Bently Nevada configuration software (e.g., 3500 Rack Configuration Software).

Criticality of Application: For machinery protection, ensure the system design and module selection meet the required Safety Integrity Level (SIL) if applicable.

Maintenance and Calibration: Regular maintenance and calibration of the entire monitoring system, including output modules, are essential to ensure continued accuracy and reliability.

Cybersecurity: For communication gateway modules, cybersecurity best practices are vital when connecting to plant networks.

Bently Nevada Output Modules are critical in a wide array of industries where the reliable operation of rotating machinery is paramount:

Oil & Gas:

Protecting compressors, turbines, and pumps in refineries, petrochemical plants, and offshore platforms.

Triggering emergency shutdowns (ESD) for critical machinery trains.

Power Generation:

Protecting steam turbines, gas turbines, generators, and large pumps in coal-fired, combined cycle, nuclear, and hydro power plants.

Initiating turbine trips based on excessive vibration, thrust, or differential expansion.

Chemical and Pharmaceutical:

Safeguarding reactors, mixers, and high-speed centrifuges.

Manufacturing:

Protecting critical motors, fans, and blowers in heavy industrial manufacturing.

Pulp & Paper:

Monitoring and protecting large rotating equipment in paper mills.

Mining and Metals:

Ensuring the safety and reliability of large crushers, mills, and conveyors.

We have the same series of models in stock. If you don't find the model you need, please contact us and we will provide you with an official quotation!

BENTLY NEVADA 129715-138-040-05-05

BENTLY NEVADA 31000-16-10-00-159-00-02

BENTLY NEVADA TK-3E 177313-02-02

BENTLY NEVADA 3500/05-01-03-02-00-01

BENTLY NEVADA 3500/15-05-05-02

BENTLY NEVADA 3500/22-01-03-02

BENTLY NEVADA 3500/50-01-03-02

BENTLY NEVADA 161204-01

BENTLY NEVADA 288055-01

BENTLY NEVADA 330400-02-00

Colour:new Warranty: 12 months

Lead Time:3-day working day Price: Please contact us

Shipping Port: Xiamen, China Payment:T/T

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online servic

Our service:

Fast delivery, and can be used with your express account.

Competitive Price

Free Shipping

One-year warranty